Impetus to Invent

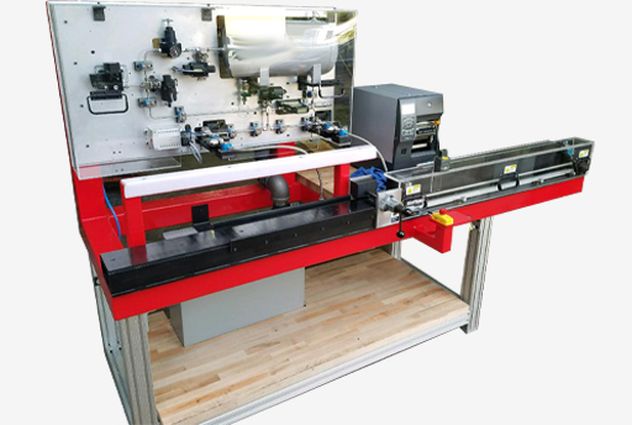

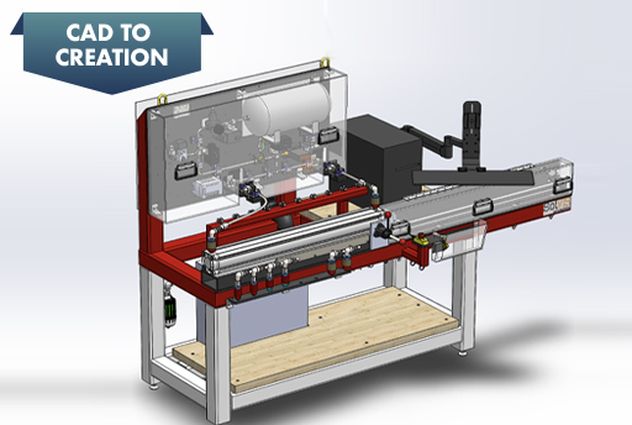

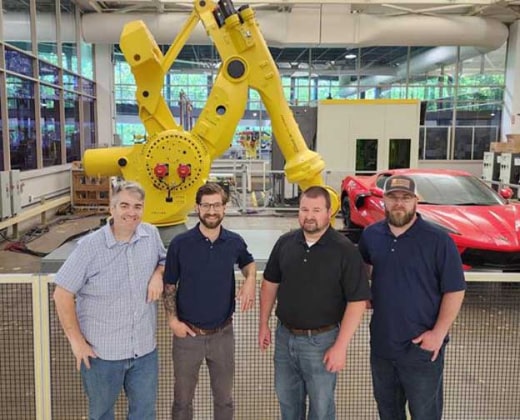

A customer’s air cylinders have a series of tests they must pass before being shipped. Invent Automation created a custom workbench to combine leak detection, flow rates at various pressures, magnet component detection, and stroke length validation. The workbench was designed to accommodate an entire product family of air cylinders with an infinite set of configurations due to body size, port size, and stroke length combinations.

The operator would scan the barcode on the work order, and the system would query the ERP system for the proper test parameters. When the air cylinder passes all tests, the system would communicate with the ERP system to generate a custom label and present it to the operator for placement.

Problem Solved

Several tests were consolidated into one workbench to reduce labor and streamline the testing process.

Lessons Learned

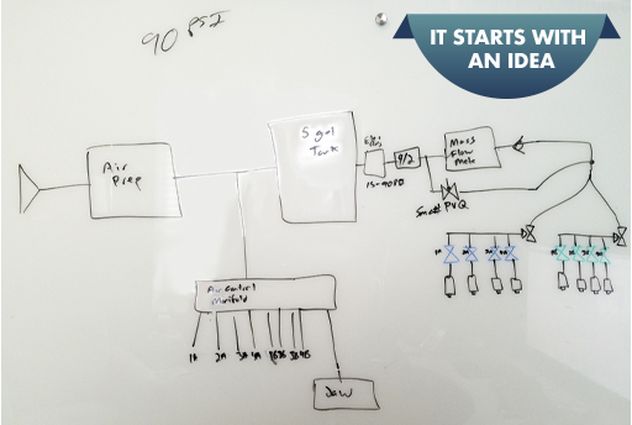

Air tanks are not necessarily leak-proof. We had to do a little welding to seal ours up and prepare it for use.

What Was Unique

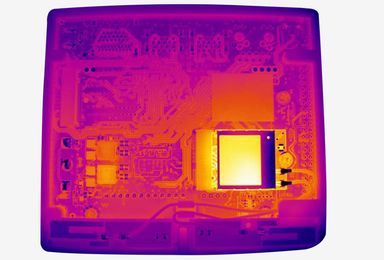

Mass flow meters are incredibly accurate at detecting small leaks down to 1 sccm but can be slow if you have to fill a large chamber full of air through their orifice. In the case of this machine, we used leak-free process gas switching to fill the air cylinder chambers quickly first, then switched over to the mass flow meter flow path for quick detection of leaks.

What Was Challenging

Integrating with the customer's ERP system can be challenging, which is why we worked closely with our client's IT group to get the data we needed quickly.