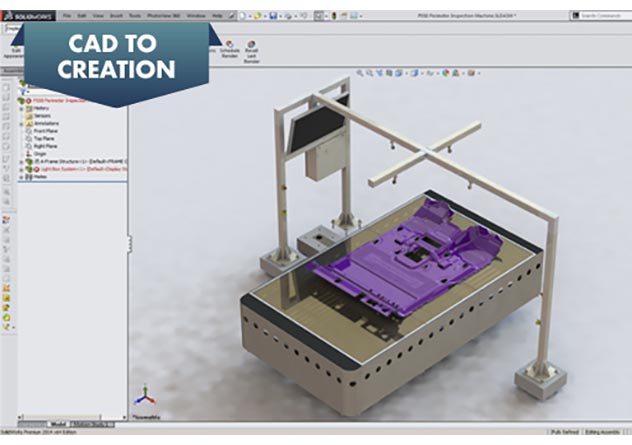

Impetus to Invent

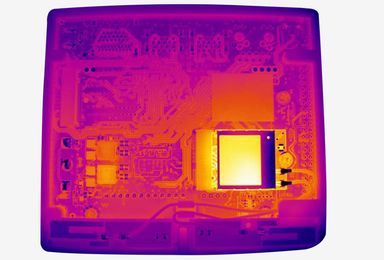

The Ford F-150 thermoformed acoustic barrier had an extreme number of holes and waterjet cutouts. The automation and operators were responsible for removing these, but if inspected manually, there was a high likelihood of an escape to Ford. What to do? It was the perfect opportunity for Invent Automation to create an amazing backlit inspection system that automatically detected if a missed cutout was not removed. The part configuration was auto-detected when two operators loaded the large product, and on a large screen, the operators could clearly see which cutout was missed. Upon passing inspection, an automatic barcoded label was applied to the underside of the system. Voila! Peace of mind and escapes were a thing of the past!

Problem Solved

Operators are, well, only human. Machine vision is, well, a machine!

Boring job made much simpler: no decision fatigue or escapes!

Barcode applied only if validated as correct.

Easy to see if a hole was missed upstream.

Lessons Learned

That pretty curve at the front of the machine was a pain to fabricate! We love to make our machines look nice, but sometimes the juice is not worth the squeeze!

What Was Unique

A very large backlit surface with many standoffs that worked for all configurations made this a highly versatile machine. No changeovers required!

What Was Challenging

A very large opaque surface had to be supported in ways that did not cast a shadow. With so many Ford F-150 cab configurations, it was a challenge to get these exactly in the right spot, but we did it!